Production speed is one of the most tangible benefits of upgrading a cold heading machine. Modern machines employ advanced feed systems, faster stroke cycles, and integrated automation that significantly reduce idle time between operations. For instance, older models may operate at 60–80 strokes per minute, while upgraded multi-station machines can exceed 100 strokes per minute without compromising part quality.

High-speed operation doesn’t just increase output; it transforms workflow efficiency. More parts per hour mean shorter lead times, allowing manufacturers to handle large-volume orders more effectively. In competitive industries such as automotive fasteners or hardware components, faster production cycles can directly translate into increased client satisfaction and repeat business. Manufacturers should evaluate their current throughput against market demand—if production bottlenecks are recurring, an upgrade could pay for itself quickly.

Aging cold heading machines often present hidden costs beyond their purchase price. Common issues include worn bearings, hydraulic leaks, misaligned tooling, and outdated control systems. These malfunctions can cause unplanned downtime, disrupting entire production lines. In real terms, just one hour of unexpected downtime in a medium-sized facility can result in hundreds or thousands of lost units and significant labor costs.

Modern machines address these concerns with robust, precision-engineered components and real-time monitoring systems. Features such as predictive maintenance alerts, high-durability materials, and self-correcting alignment mechanisms reduce the frequency and severity of breakdowns. For manufacturers, the result is a smoother workflow and a shift in focus from constant repairs to optimized production. Monitoring repair logs and downtime frequency can help determine the right moment to invest in an upgrade, before disruptions escalate into major losses.

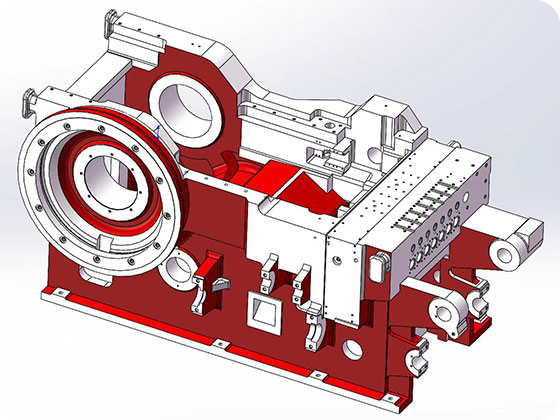

7 Station Cold Heading Machine

Precision is critical in cold heading operations, where even a fraction of a millimeter deviation can affect assembly, performance, or safety. Older machines, particularly those without automated adjustment features, are more prone to producing inconsistent parts, resulting in higher scrap rates and rework.

Upgraded machines leverage technologies such as CNC-controlled dies, automated alignment systems, and temperature-stable components to maintain tight tolerances. For example, a manufacturer producing fasteners may see dimensional consistency improve from 95% to over 99.8% after upgrading to a modern system. This consistency not only reduces waste but also enhances reputation for reliability. Regular measurement and statistical process control (SPC) combined with modern machinery ensure that high-quality parts are produced reliably, minimizing costly errors downstream.

Maintenance is often an underestimated cost in manufacturing. Older machines may require frequent lubrication, component replacements, and emergency repairs, all of which add up over time. Modern cold heading machines incorporate features like self-lubricating bearings, modular replacement parts, and predictive maintenance software to minimize intervention.

A comparative analysis can be eye-opening: an older machine might incur $10,000–$15,000 per year in maintenance and repair costs, while a new machine with intelligent monitoring and durable components could reduce that figure by 40–60%. Beyond direct savings, reduced maintenance means fewer interruptions in production schedules and less strain on technical staff. Evaluating the total cost of ownership, not just upfront purchase price, is essential when deciding on a machine upgrade.

Balancing speed and precision is the hallmark of an effective cold heading operation. Modern machines achieve this through synchronized controls, optimized die design, and real-time feedback systems. They allow operators to increase throughput without sacrificing accuracy or reliability.

Consider a facility upgrading from a single-station to a multi-station cold heading machine. Output can increase by 30–50%, while defect rates remain low thanks to automated monitoring and adaptive tooling adjustments. The combined effect is higher profitability, better resource utilization, and consistent product quality. Manufacturers should assess both their speed and quality goals when planning upgrades, ensuring that new equipment supports efficiency while maintaining tight tolerances.